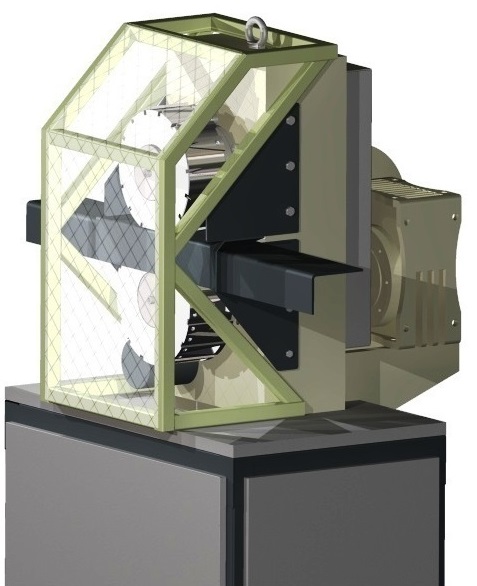

Wall Bracket Machine

- The production of all series of wall brackets which are the most time consuming and expensive to produce in Cable Tray production can be produced with a single machine and a single die

- -All of the "Wall Brackets" from 10 cm to 60 cm can be produced without the need of any changes with the same roll sheet as program

- The initial investment cost for manufacturers of newly manufactured cable tray manufacturers is very low.

- By applying the existing eccentric, hydraulic presses in the plant, a manufacturing production line can be established with roll form and docoiler.

- Metal industry will reinforce our claim on sheet metal processing with this machine, the high and precise technology used in the manufacture and production of the wall console, quality, long life, zero operating cost and zero labor will be noticed by your competitors.

- You will see the redundancy of time and money spent in your cable tray factory, requiring a high-quality employee, qualified sheet metal punching patterns, and simple molds

The production of all series of wall brackets, which are the most time consuming and expensive to produce in cable tray systems, can be manufactured with a single machine and a single die. With the same roll sheet, all of the "Wall Brackets" from 10 cm to 60 cm height can be produced without the need of any changes.