WHEEL WEIGHTS CHOPPING AND MARKING MACHINE

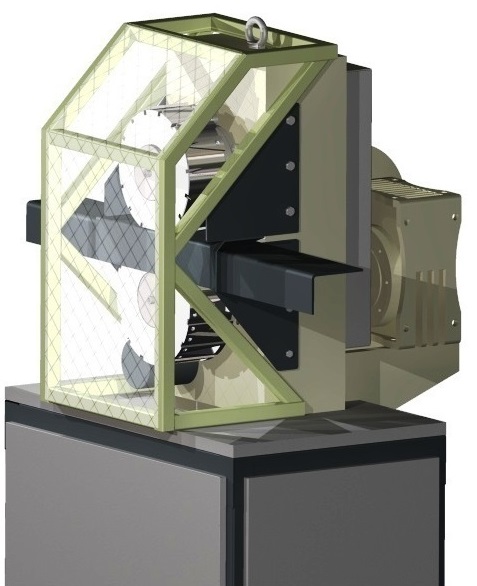

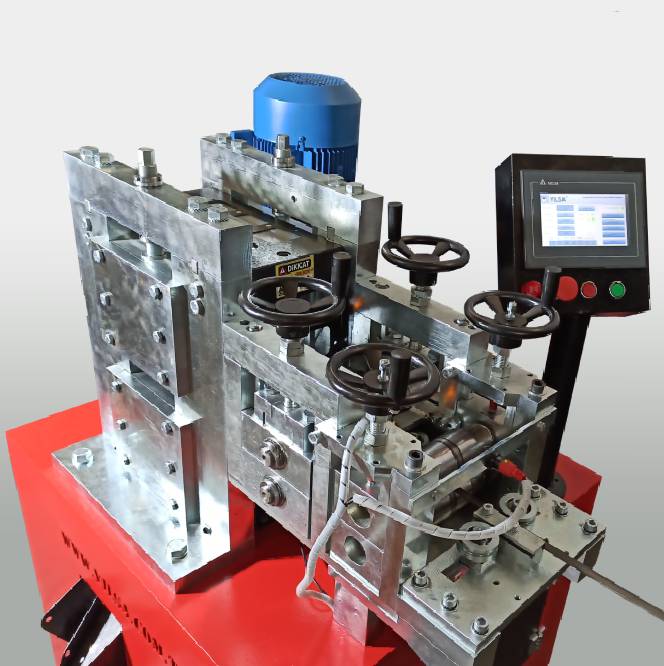

Rotary Punch works differently from conventional presses. As the name suggests the machine cuts and marks the sheet metal strip as it rotates. There are two molds containing male and female patterns. With the rotation of the rollers, the opposite female and male molds come on top of each other, and the cutting and marking of the sheet in between takes place. Unlike other presses, the process is not instantaneous, it is done pointwise as in cutting with scissors. This rational system brings with it many advantages.

Our machine makes cutting and marking of fed metal strip without wastage. The cutting length is the distance between the dies.The chopping width is the same as the width of the fed sheet strip. The weight of the chopped pieces can be adjusted by changing the width of the strip.

OUR TECHNIQUE

Low energy consumption: 83,300 units/kWh

Rapid Production: 100,000 units/hour

Obvious marks

Burr-free and smooth-edged cuts

TRADITIONAL TECHNIQUES

High energy consumption: 20,800 units/kWh

Slow Production: 25,000 units/hour

Blurring marks

Burr products with distortion of cutting angles

Our machine cuts without wastage with high precision in production. Rotary production is continuous so production is faster: 100,000 units/hour. Since cutting and marking is rotary, production is made with low energy costs with a smaller electric motor. Our technology also brings low maintenance costs and long die life. The rotary mechanism is not vertical, so the machine dimensions are smaller and can be used in tighter spaces. The rotating working technique prevents vibration, and the machine dimensions are small, these two features make it possible to use the machine even on intermediate floors. Rotary operation also allows the machine to be fed by itself, it does not require an extra feeding unit. Considering all the advantages compared to other equivalents, the price is more economical Wheel Weights